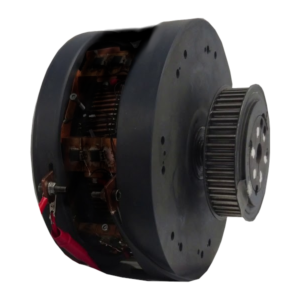

Multi Phase Axial Flux Motors

Low Cogging Torque, Longer Service Life and more Power

Brushed Axial Flux Motors

Low Voltage Motors with Brush Commutation and Simple Drive Control architecture.

Pure Torque Controlled Drives

Maximizing System efficiency in Motoring and Regen Modes

Customize your Package

Ready-To-Race-Technology with Custom Motor Design Support

Previous

Next